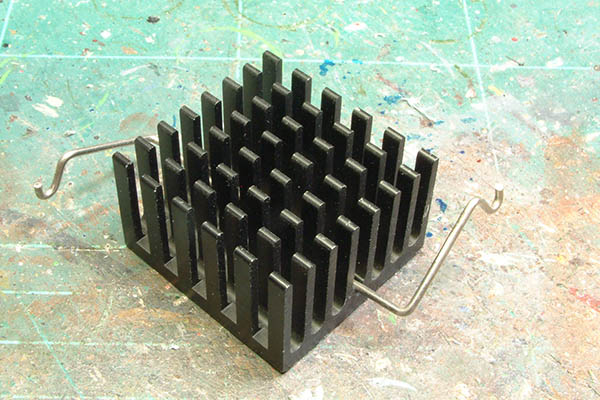

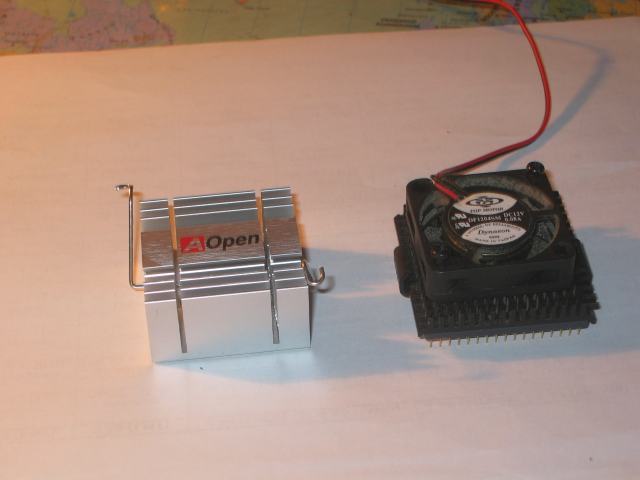

I have a pile of heat sinks that I've been putting off cleaning. These are the kind that have metal spring clips holding them tight. Here are two examples:

The last time I removed the steel clips to get extruded price on the rest, it was a pain. I used pliers to try to pry the steel clips loose, and half the time the steel snapped. The extruded part of the heat sink is usually bent to wrap around the steel. I'm considering just selling the container as dirty AL.

Does anyone have any good techniques for cleaning these? Has anyone else found them to not be worth their time? Just curious of other's opinions.

- Cleaning Up Northbridge Heat Sinks

- Cleaning Up Northbridge Heat Sinks

Register To Reply

Register To Reply

Grrrrrr.....

Grrrrrr.....

Bookmarks