http://www.scrapmetalforum.com/elect...ese-chips.html

Here is the link about the black plastic coated pieces of copper the white grease is thermal grease.

|

|

http://www.scrapmetalforum.com/elect...ese-chips.html

Here is the link about the black plastic coated pieces of copper the white grease is thermal grease.

|

|

They are #2 copper, just throw them in your #2 copper bucket. If you brake them apart your losing wieght.

|

|

Yesterday i took some apart useing a torch set to low heat. Heat up the copper from the bottom. Holding the copper with pliers as it heats up you can feel the soldier release the finns just bump it on something and it will come apart. But like happy said leave it togather if your yard will grade it as #2 copper [clean] the al. will add a little more weight to it.

The fastest way to separate the aluminum fins from the copper bottom is with an air chisel. Clamp in a vise and bust off the fins with the air chisel. Takes only a few seconds per piece. On the ones with the copper slug in the middle I press them out with a hydraulic press.

|

|

The round heatsinks with the copper slug in the middle...I get alot of those from High end desktops like Toshiba/IBM/HP.

If you do not have a press or a hammer and punch, then you can take a hacksaw and saw between the fins...it doesn't take but a minute or two...then use a screwdriver and hammer to separate the Al from the Cu...

Also look for heat sinks that have a slab of copper on the bottom coming from Acer desktops. Can use a cold chisel or woodchisel and hammer to remove.

Last edited by CFoote; 06-27-2012 at 12:39 PM. Reason: spelling

Christopher Foote

Operations Manager, REWORX of North Alabama a 501(3)C non-profit Company

Office: 256.260.1791

Cell: 256.606.5604

chris.foote@capna.org

I have gotten several in different configurations. I fired up my propane turkey cooker and place the heat sinks in a SS wire basket(used to cook french fries). Once the heat sinks are hot enough to melt the solder that holds the copper to the Al I grab the heat sink with pliers and knock the heat sink against something solid and the copper falls out. Mike.

"Profit begins when you buy NOT when you sell." {quote passed down to me from a wise man}

Now go beat the copper out of something, Miked

|

|

I thought I would bring this thread back to life again: 1. I have a bucket full of heat sinks 2. This thread seemed to be talking about two different things (CPU heat sinks & TO-220 packages attached to heat sinks). I found a heat sink with copper core today in my bucket of heat sinks. I was reading this thread for the first time today, to find out how to separate the aluminum from the copper core. I put the heat sink with core attached, in freezer for 30 minutes. Then put just enough of heat sink into a vice to secure it good. Next used a propane torch to heat perimeter of aluminum, trying not to heat copper core as much as possible. Total amount time applying heat was less than 1 minute, took a 1/2" punch and hammer popped out copper core in two taps.

This a CPU heat sink with aluminum fins and a solid copper core (a after market kit for better cooling).

The inside view of a TO-220 package, showing the metal frame attached to the die. The metal frame is usually connected to a heat sink.

a. heat sink compound b. heat sink c. TO-220 package d. back of TO-220 package with compound applied e. heat sink and TO-220 package attached f. isolation washer and insulation strip (sometimes used to insulate TO-220 metal frame frame from heat sink.

This thread already had some good info., just trying to add to it and hope this helps. The other important addition is that there are many types of heat sinks. Some are high grade extruded alloy aluminium 6061 or 6063. Other material used in heat sinks may be combinations of material including aluminum, copper, brass, and steel, either combined or a single material. Many times there will be little pins attached to extruded aluminum heat sinks, these pins are soldered to circuit board to both secure and ground the assembly. Make sure to check these pins, as they will be either steel or brass that will be tin platted. Need to remove pins if you want to get paid for 6061 or 6063 aluminum (don't cheat yourself at the scale).Also TO-220 is not the only type of package that will have heat sinks attached, TO-3 packages will also sometimes have heat sinks attached, as well as other package types. Hope this helps someone.

Last edited by bigburtchino; 01-17-2016 at 08:05 PM.

Bigburtchino, I used to get a lot of the Cu/Al heat sinks like the one in your first photo. When I did I would put them in a vise in the same position as in the photo. I would spread apart two of the fins and cut the Al with my saws-all. Once the Al was cut through the Cu plug would fall out.

Both our methods use energy in one form or another and for me it depends on how many I have to do what I use. I wish I could get paid enough not to think about separating the Cu for the Al. Thanks for sharing your methods. Mike

|

|

I just use a 1/2 ton manual press to remove the copper

Currently looking for a job in or related to scrap/recycling. Relocation is possible for the right offer.

|

|

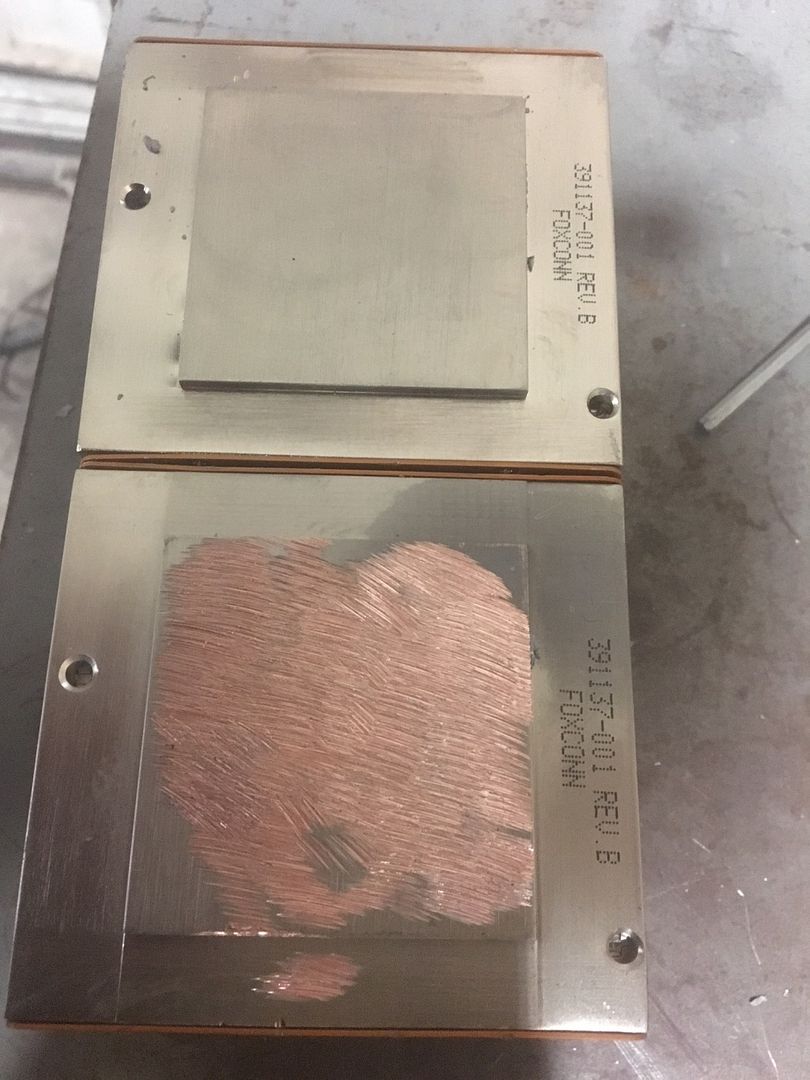

Here is an example of some coated copper heatsinks that you can get a lot better price on. They look like aluminum ones, but are quite a bit heavier, so they are easy to separate out. If a heatsink feels heavy I always have my guys scratch it or hit it with a grinder to check.

Last edited by HiTechMike; 01-20-2016 at 06:11 AM.

Life is tough, but it's tougher when you're stupid. - John Wayne

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks