One of the challenges in this project was the coal pulverizers. These were used to crush coal to power the plant. The dust is highly explosive.

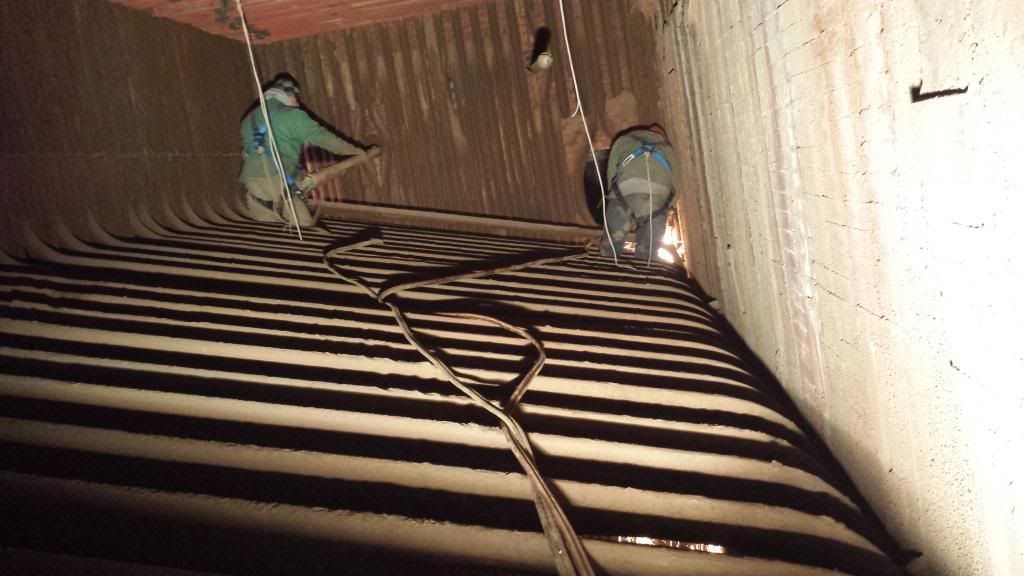

This was one of the conveyor belts that brought coal into the plant, also a concern with coal dust. It was located at the opening of our ramp, so was taken out early.

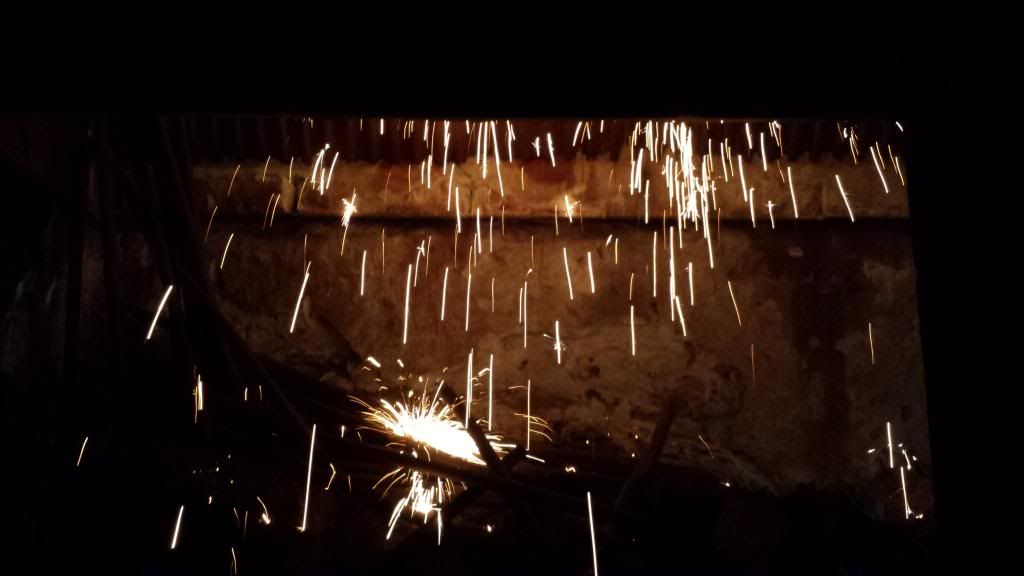

Partial demolition of the pulverizer.

A little further along.

A drive wheel used to move coal down the conveyor to the pulverizers.

A picture of the total destruction of the pulverizers along with the weight will be posted when we have completed this portion of the project. There were four pulverizers, two for each boiler. One had already been removed and we are working on three. A lot of research went into how to dismantle these giants. A lot of the information was provided by this web site. We lucked out because of instead of using different gasses to remove the chance of explosion, we let mother nature help out. The pulverizers were filled with frozen water and we cut them down before spring hit. Thank you mother nature. I know we are not allowed to talk religion on the forum and many native American Tribes considered mother nature as an entity. After this experience, I am not sure they were right in many ways.

Register To Reply

Register To Reply

-

-

Bookmarks