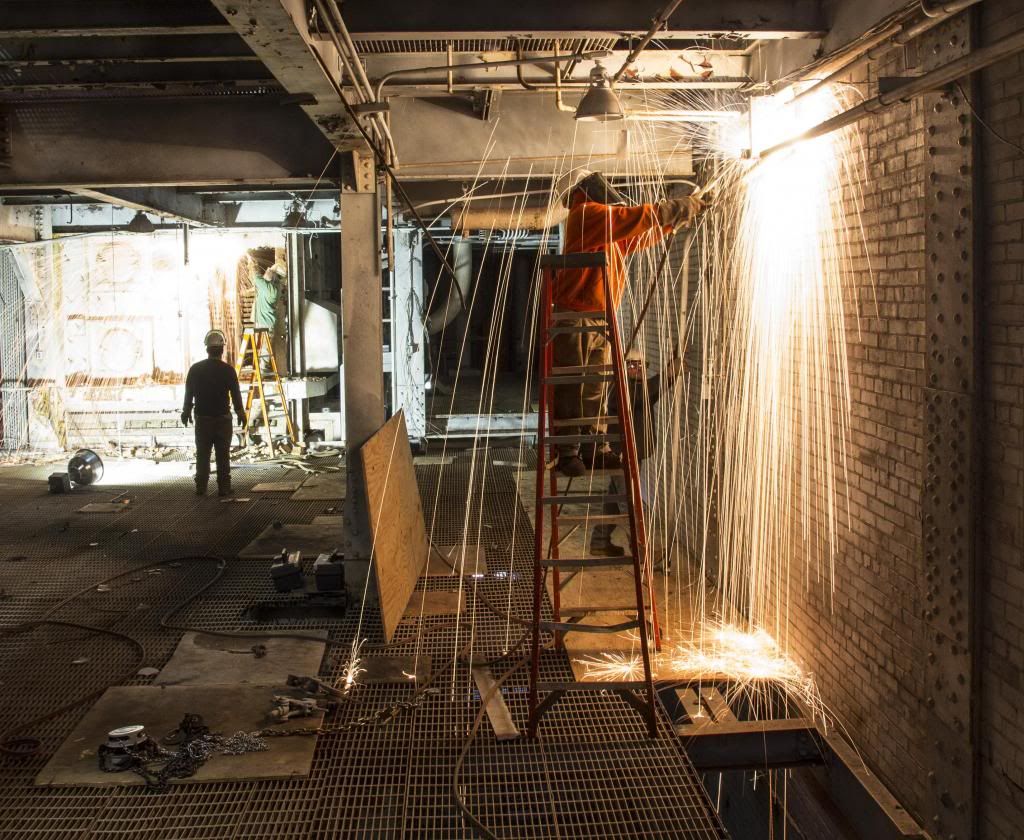

Shower of sparks, following are some professional pictures of torches and the sparks produced. The first picture is taking off a piece of angle iron and pipe from an I-beam. The I-beams will stay and everything has to be removed from them before construction. This is tricky burning off the steel without gouging the I-beam. Everything not flat on the I-beam will have to be taken off later with a grinder. Motivation for taking it off with the torch the first time, we will spend less time holding a grinder over our heads to smooth them off.

The next picture is one of the torch guys cutting on a coal chute lined with concrete. A special tip is used called a gouging tip. It allows most of the heat to be directed into the metal and not into the concrete. When concrete is heated, it explodes like a sand blaster making it uncomfortable and causing excessive slag to be created.

The lesson learned over time is that the sparks travel through the cat walk 10 stories and are still hot when they reach the basement. Therefore you cannot have one person working below another. Anther thing, nothing combustible can be left anywhere. We try not to have lunch bags, trash, t-shirts, sweat shirts, etc. inside the plant unattended. Because the power plant is all steel, we have to be concerned with what we bring in. Another concern is the propane and oxygen cylinders. We have spark resistant blankets to throw over them. We have been very careful about where we fill the quickie saws as well. In some of the pictures you can see plywood. As material is cut we have a laborer that goes around and covers holes with plywood so no one gets hurt. Each torch person is suppose to be aware of all plywood on all floors below them and periodically check for hot slag.

Bookmarks