But now I know better.

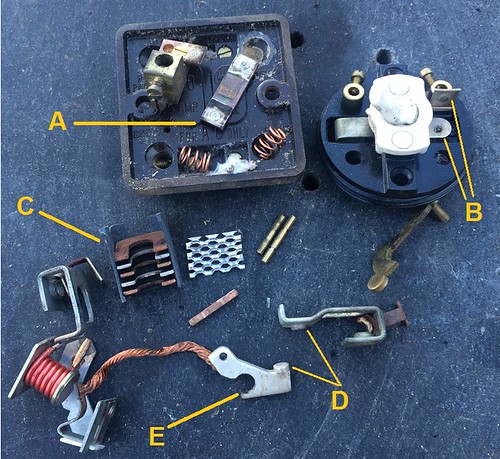

A - (3) Bakelite switch missing the cover.

alright silver plate on heavy copper, and some nice copper springs (another one to remove also).

Not sure if the bumps are silver right through, will sand them to see.

B - (1) white switch, very thin electroplate (they got good at saving money whenever these came out), might sand it a bit - I'll not bother too much with these in the future. Interestingly the base is Bakelite. The bump on contact was just embosed (stamped) through from other side.

C - not sure how this bit worked just sort of smashed the long switch to bits (2), only way to get in, appears to be some kind of heat sink, and has a kind of cardboard heat shield holding the plates. Alumium heat vent, some kind of copper coil, very interesting, nice little bits of brass for future engineering projects (I make micro scale things).

D - massive Silver buttons, nearly thought E was silver too (wishful, only Alumium) the weight was from the button!

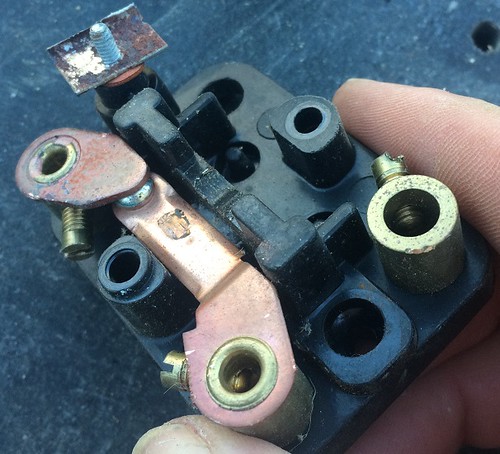

From the Switch box, quite a nice button of silver, copper is riveted on so will take some work to separate these.

Well that's my day so far. Happy Hunting.

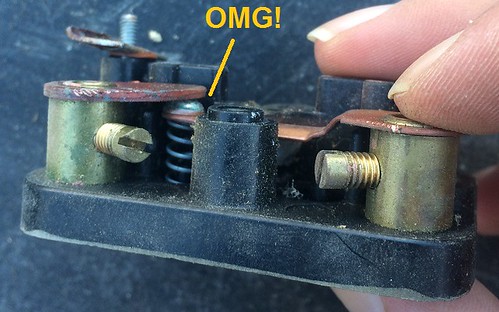

- Nearly wrote these off!!!

- Nearly wrote these off!!!

Register To Reply

Register To Reply

Bookmarks