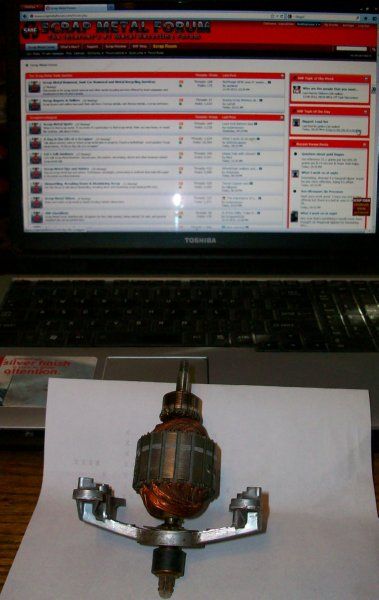

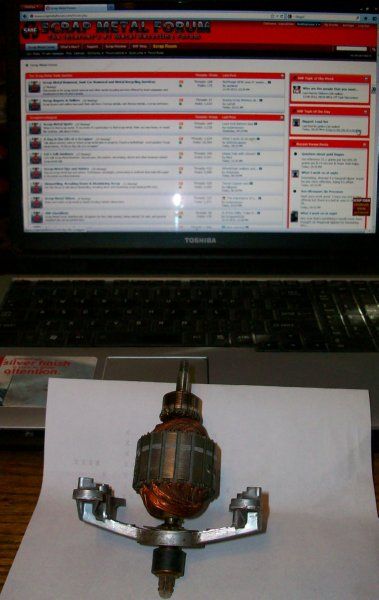

I know where it came from but not the name or how to break it down and remove the copper

any help please

I know where it came from but not the name or how to break it down and remove the copper

any help please

|

|

I break that down by knocking the brass (?) end off on the bottom and tossing it in the brass bucket, pulling the cast zinc (?) arms. Sometimes there's a brass ball & socket thing where the shaft goes through the arms. Pop that out & then throw the arms in the diecast bucket, and then throwing the wound shaft in the motor bucket. Done.

The time you spend learning Tourettes while you're fighting with trying to get 75 cents worth of copper out of an item your yard oughta pay ~30 cents for as is could be better spent elsewhere.

I'd say every scrapper oughta do it once, though.... just to learn WHY they won't do it again.

Out of clutter, find simplicity. --Albert Einstein

|

|

Use a Sawzall to cut the copper wires very close to both sides of the armature. The use a small stiff rod or screwdriver to pound on and force the cut off wire through the armature.

People may laugh at me, but that's ok. I laugh all the way to the bank.

|

|

40 cents is not going to cover your time and the wear and tear on your tools. I put all of my rotors in with the transformer and motors. 30 cents a pound as-is.

I buy and sell all types of scrap and escrap. I buy specialty and hard to sell escrap. I buy resale items. PM me or contact me at jghilino@hotmail.com

I AM ACTIVELY BUYING ESCRAP OF ALL TYPES. BOARDS, RAM, CPUS AND MUCH MORE

|

|

I save all the rods out of printers. ya can make all kinds of neat tools from them.

"anyone who thinks scrappin is easy money ain't doin it right!"

|

|

armature.

I do them the same, too time consuming.

Or you can look here:

http://www.scrapmetalforum.com/scrap...ture-arms.html

Thanks for the info I think I will just turn in as is BUT auminer I will try one time just to see why I should not do it anymore.

|

|

Olddude, great minds think alike..those rods take a beating an great use as a tool. I use them for a variety of reasons.

Sirscrapalot - Has an old heavy table leg he uses now an then as a bashing tool.

|

|

Bullrider, that's how you learn, try it once and you'll know what's involved. Back in the day I used to take the copper out now I just put them in with my motors and transformers. If you have a band saw you can cut the armature in half and then using a thin rod of some kind punch the copper down and out of the armature. That's how i used to do it.

|

|

Yes it did. his question was what is the name of the part, i said it was a rotor. Some people call it armature some call it rotor, but same thing. I know how to get the copper out i was just stating its not worth it , because its not worth it. Unless we are not allowed to give advice on the forum?

Rotor (electric) - Wikipedia, the free encyclopedia

|

|

|

|

i did not miss the point, he asked how to break it down for copper, i said dont do it so it think that i covered it good enoughit goes in the motor / transformer pile like i said

|

|

the answer to that has been posted plenty of times in this forum, so i was offering advice instead

|

|

Just because you don't think it's worth your time dose not mean it's not worth somebody else time. That's why I said to go ahead and brake it down then you'll be able to tell if it's worth your time or not. not in those words but that is what I ment.

|

|

I just cut one end off flush with a 6in angle grinder with a cut off wheel and use a punch and hammer to hit out the copper out of the stator, i dont process the rotors as they are not worth my time. But the process would be the same. I only do about 50 motors / compressors a year. Ill go ahead and post the video again since no one can find it in the forum from the last 3 times i talked about it.

|

|

The question was not about the stator it was about the armature. I take the copper out of stators too but even some stators are not worth my time but other people might do all stators. No one should try to tell someone what is worth doing for only they can determin that for themselves. Yes it is fine to give other options after you answer their question first. I know of one yard that will not buy armatures as electric moters so he needs to check with his yard before mixing them. This same yard that dose not buy armatures also wants motors seperate from transformers even though they pay the same price for them. my .02

|

|

Normally I'd bash it at the bearing & the Ali will fall off. The bronze bearing might break in half too, or bash it again.

Then I bash the contacts & they break apart & the bits are solid copper with insulation stuck in it.

I use a meat cleaver to remove the loops at one end & then pull out the copper wire from it.

Sometimes the insulation is solid & won't let you do that. I burn those off in a fire & the snip the loops & pull them out.

There are currently 2 users browsing this thread. (0 members and 2 guests)

Bookmarks