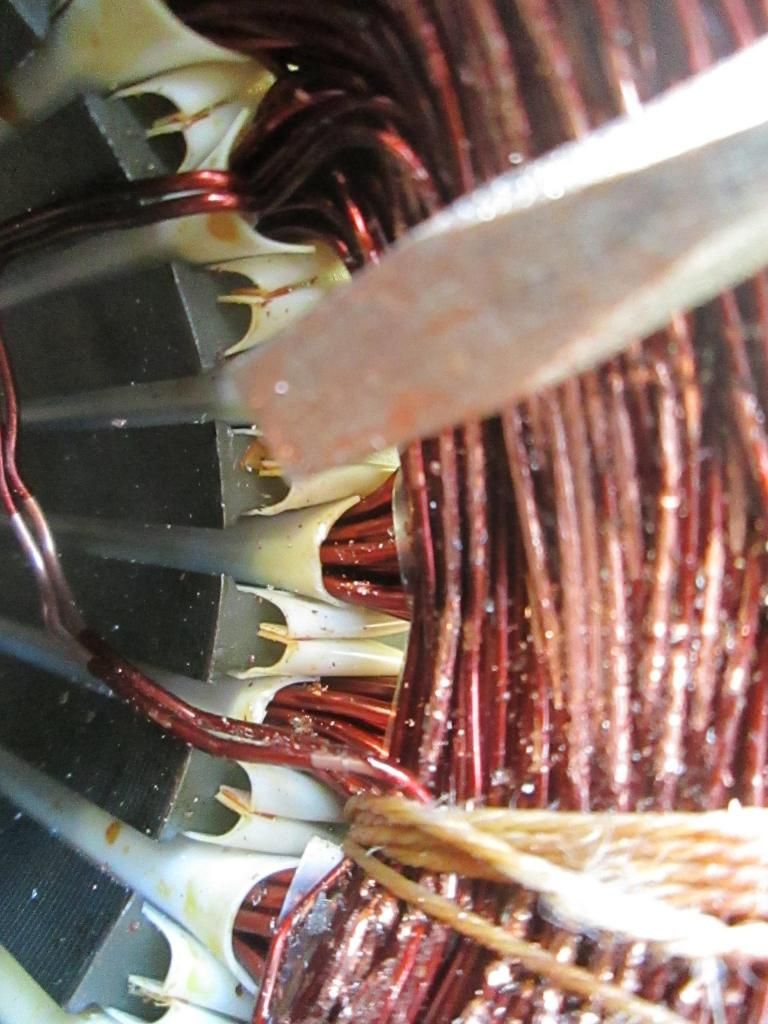

cleaning compressors today and ran into a couple oddballs, mixed windings in the motors.

[IMG]

[/IMG]

This got me thinking.... duhn duhn duhn

How could one know if the motor was wound this way before cutting?

Where were the loops of copper located in regards to the Al. Well after some rigorous scratching I found out this.

If you scratch the top of the loop or outside (side closer to the outer case) then you would see Al.

[IMG]

[/IMG]

If you scratched the inside of the winding (closest to the rotor) you would see the copper

[IMG]

[/IMG]

Thought this might help someone out... keep an eye on the inside

[/IMG]

[/IMG]

[/IMG]

Register To Reply

Register To Reply

Bookmarks