Originally Posted by

olddude

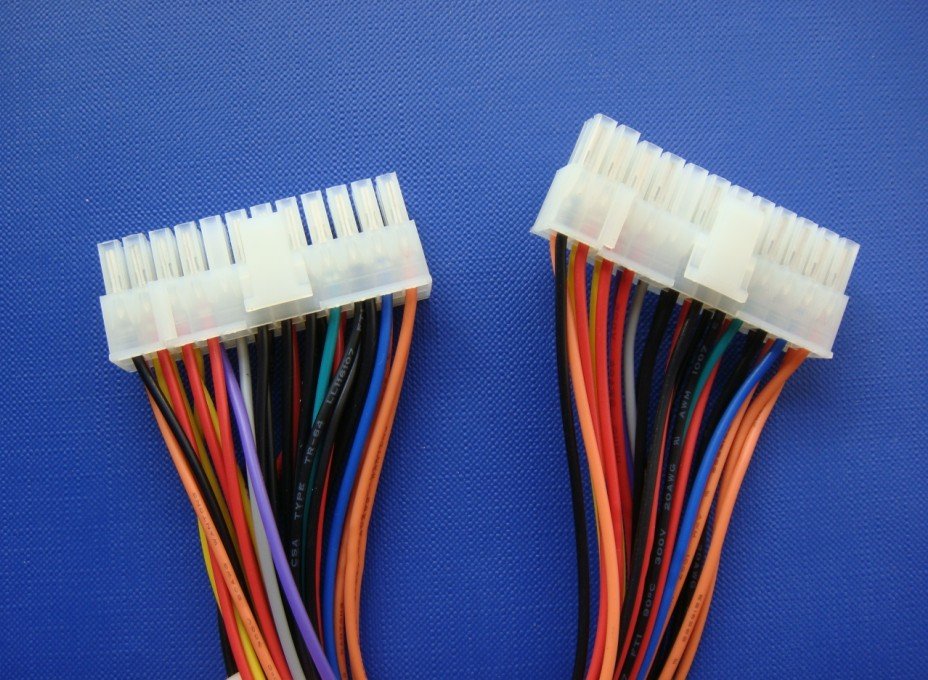

unless you can find an economical way to strip them. if you do let the rest of us know.

Actually, there is a way. Pyrolsis.

In a nut shell, this process involve heating the plastic (wires in this case) in an oxygen free environment (a SS reactor) to the point of evaporation, around 500-600 C.

Distilling and condensing some of the gases back to fuel (e.g. diesel or other longer C chains) and burning the rest of the gases.

What's left in the reactor is the metal wires + carbon black that can easly seperated by sifting.

4 products are obtained: Clean wire, Carbon black, liquid fuel and combustible gases.

I have experimented with this before, using a small pressure cooker and copper piping loaded with 1 pound of wires each time. The combustible gases fitted with a bubbler and burned under the reactor once the reaction had started... in a sense, this system is somewhat self supporting.

I have never scaled up this process, mainly due to lack of room and supply of wires, but my estimates were and remains that the reactor should hold around 150-200 lb of high gague wires, and electrically heated.

It takes some setup and there is a learning curve, but it can be an awesome thing to do and may be very lucrative assuming you find a use/buyer for the products.

Register To Reply

Register To Reply

Bookmarks