Originally Posted by

Proton

If anyone is stripping these transmissions down to get clean aluminium price, I'm in need of a couple of parts.

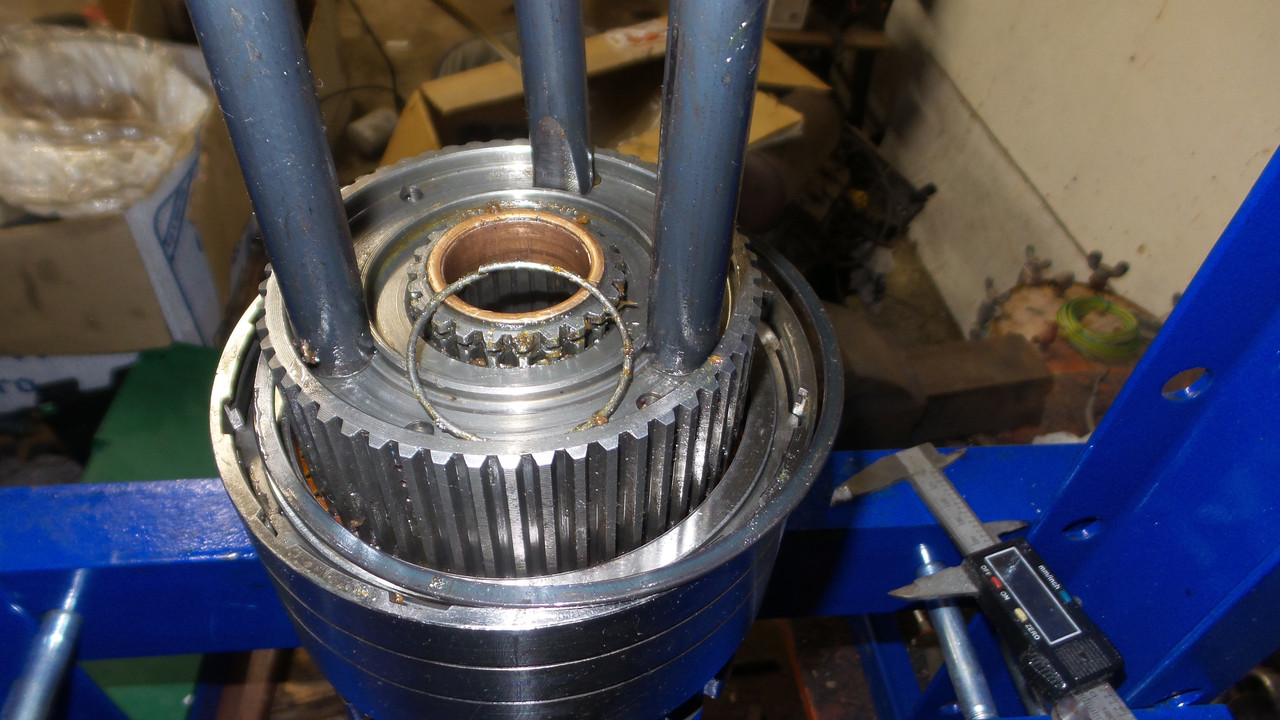

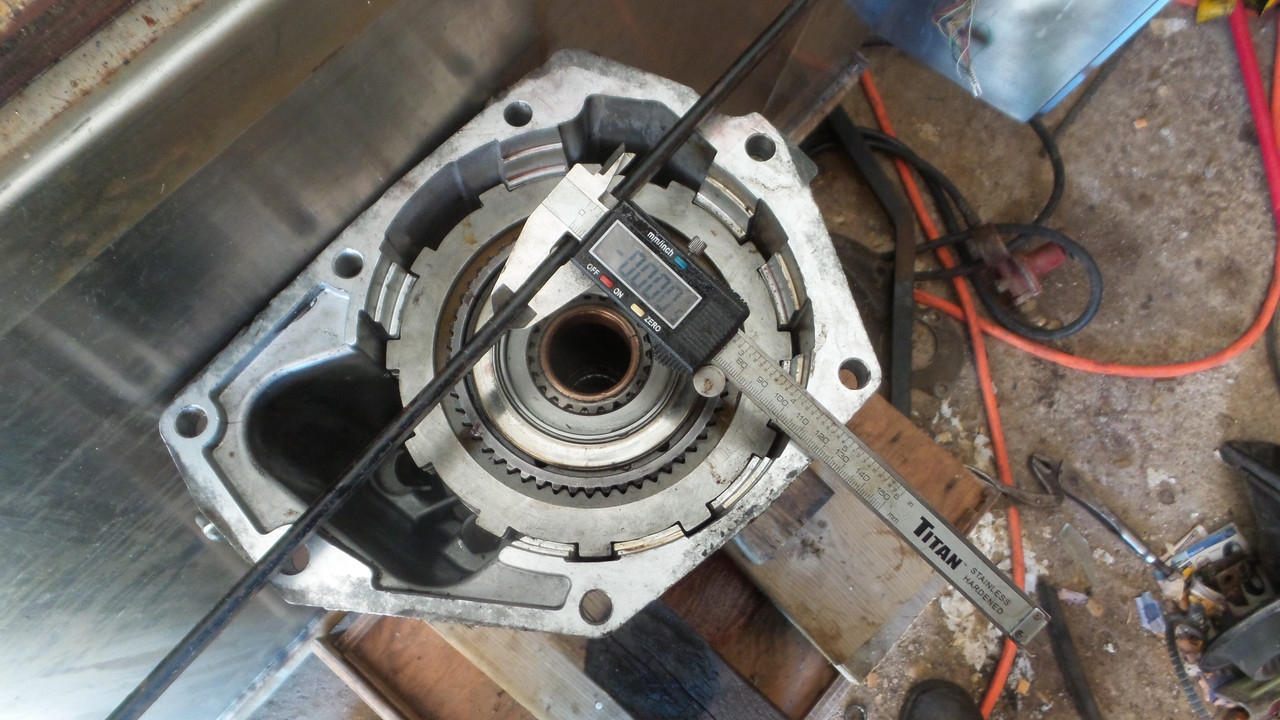

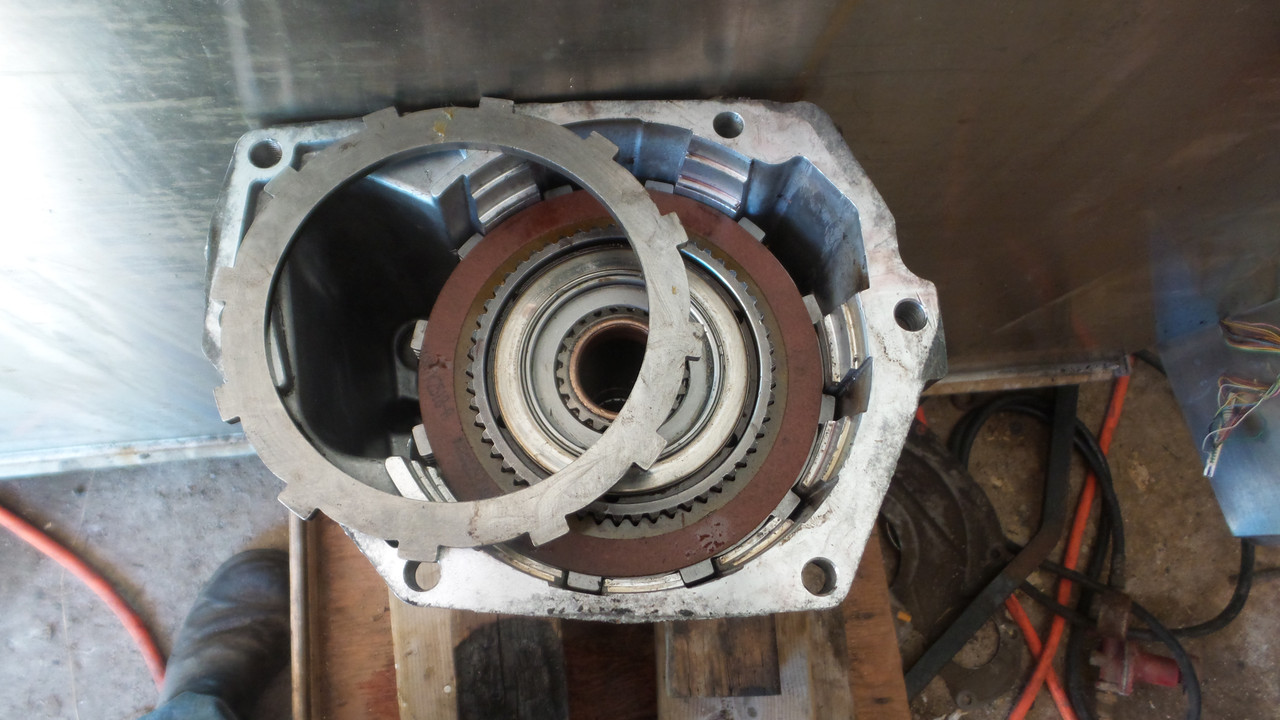

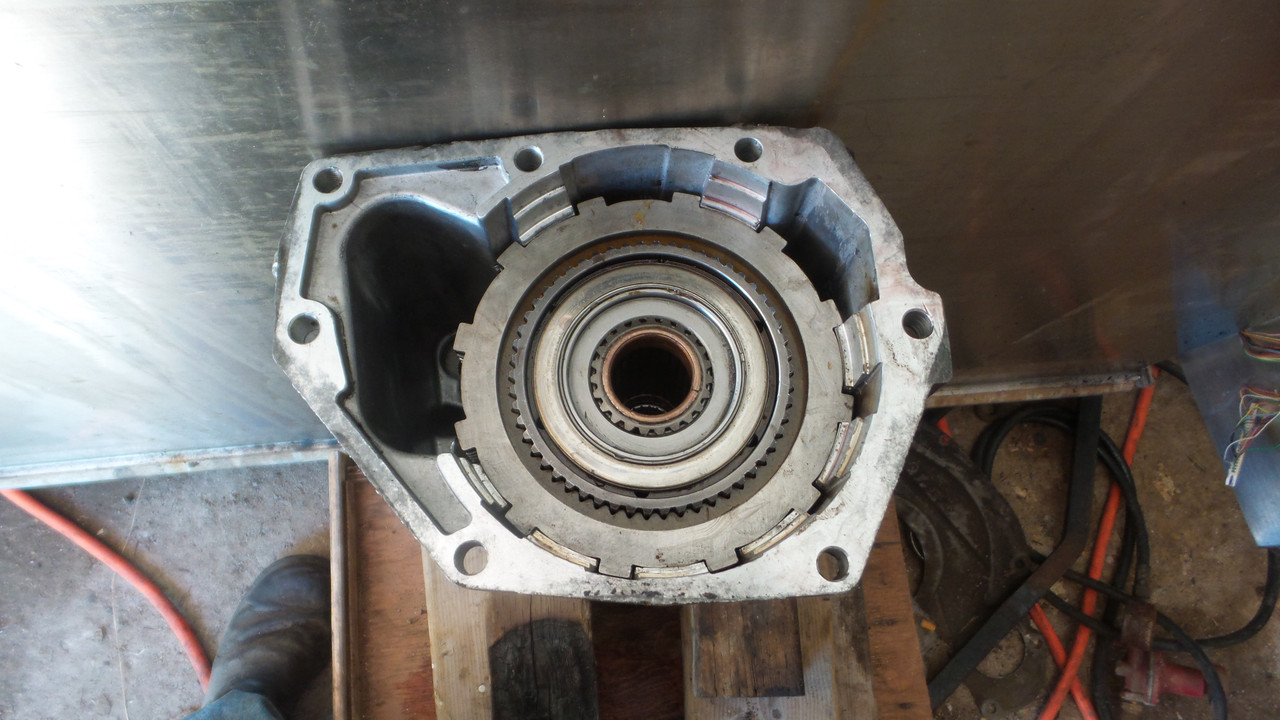

The fellow who previously rebuilt the 46RE left out a thrust washer which lead to a premature burn out of the overdrive clutch packs then I need an 0.060 snap ring from the rear forward drum.

The current snap ring measures 0.088" thick which is much to tight against the clutch pack.

It's the snap ring from this package that I need in an 0.060.

https://postimg.cc/image/jgbo886yf/

Readers may disregard this request, made a call to one of the transmission shops that I used to sell cores to years ago that operated as a father and son operation.

Bill Sr. and Bill Jr. learned this morning that the father passed away several years ago and that the son retired last year and that one of the long time shop employee's purchased the business.

Gord the new owner is ordering the parts I need to complete my transmission rebuild, thankfully I do not have a customer waiting on the return of his vehicle standing over my shoulder. I'm not that good at dealing with an impatient public.

The transmission is for a personal project, I bought a 96 Dakota in mint rust free condition. Previous owner removed the automatic transmission then found that the replacement trans would fit behind the V6 but not communicate with the ECU or the TCM.

The transmission he had purchased used was a 44RH which uses a mechanical governor with mechanically linked shift linkage, the 96 Dakota was the first year Chrysler used the electronically controlled transmission.

I spent the best part of a month looking for the electronic transmission, plenty of 4x4 stuff out there but I needed a transmission for a 2 wheel drive, fortunately I found one from a 97 Dodge Ram 1500.

The Ram with the larger 5.2 engine uses a beefier 46RE transmission, by using the torque converter from the V8 engine it will work behind the smaller V6.

Scrap yard wanted $550.00 for a core then another $250.00 for a return core, they sill have their core and my folding currency is still in my pocket.

The rebuild kit I purchased came with frictions, new steels and seals $220.00 with another $120.00 for a new torque converter, probably could have reused the old one. But on these lock up converters there is no drain plug and no sure way to flush them totally clean, it's not the burnt oil but the metal filings that will come back to haunt you.

The 46RE looks identical the the 42 and 44Re the later are used behind engines of lesser horse power while the 46RE used with gasoline engines while its sister transmissions the 47 and 48RE's you'll find behind the earlier diesels.

With the larger internal parts having more mass I'm probably going to be sacrificing fuel mileage, but on the other hand the new rebuilt 46RE will probably outlive the truck.

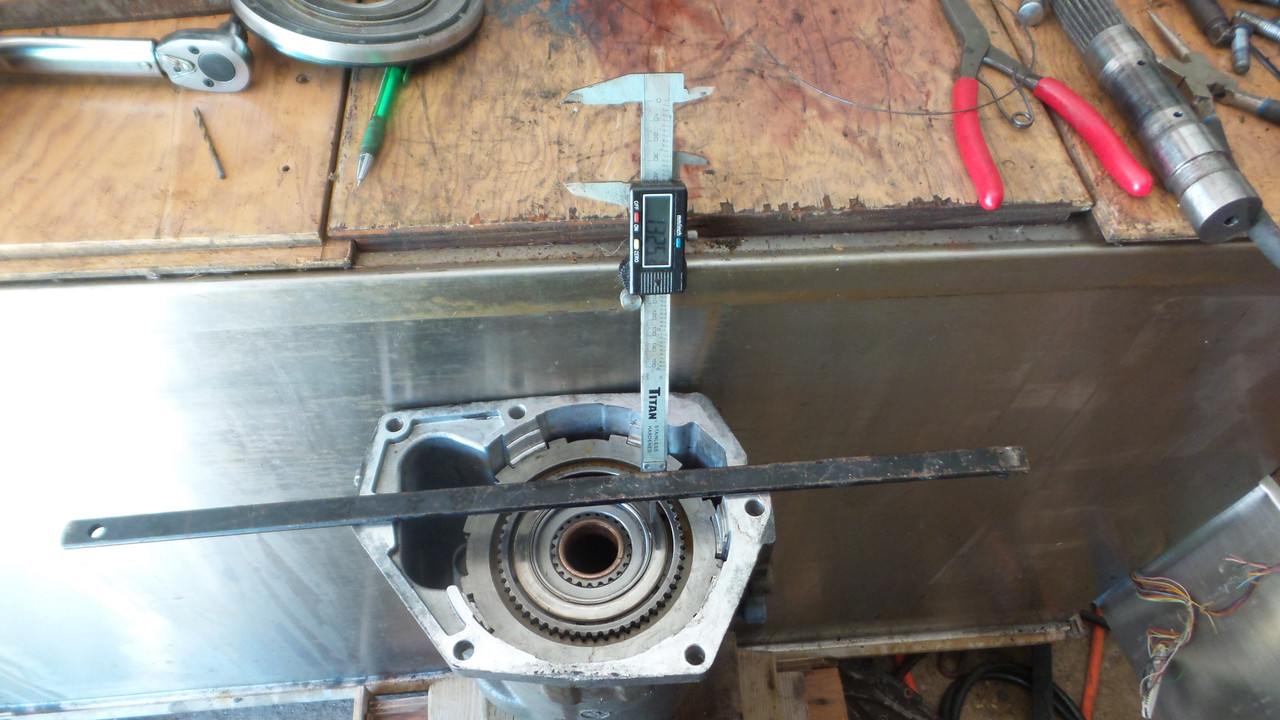

For those contemplating a rebuild it's not that difficult, most of the jigs used for compressing the various springs are easy to make in the home shop, the spring used on the rear overdrive is compressed to 800 lbs. You need a hydraulic bench press to remove the snap ring that keeps this heavy spring under pressure or a pre-paid funeral plan.

Plenty of youtube videos out there but most only give half of the story, your best bet is to purchase the rebuild manual then build your transmission to spec.

Register To Reply

Register To Reply

-

-

Bookmarks