Heading out to my favourite landfill in another municipality, usually good pickings at this site it's a rich neighbourhood full of summer inhabitants.

If anything of interest is found will post pictures of my treasures.

Heading out to my favourite landfill in another municipality, usually good pickings at this site it's a rich neighbourhood full of summer inhabitants.

If anything of interest is found will post pictures of my treasures.

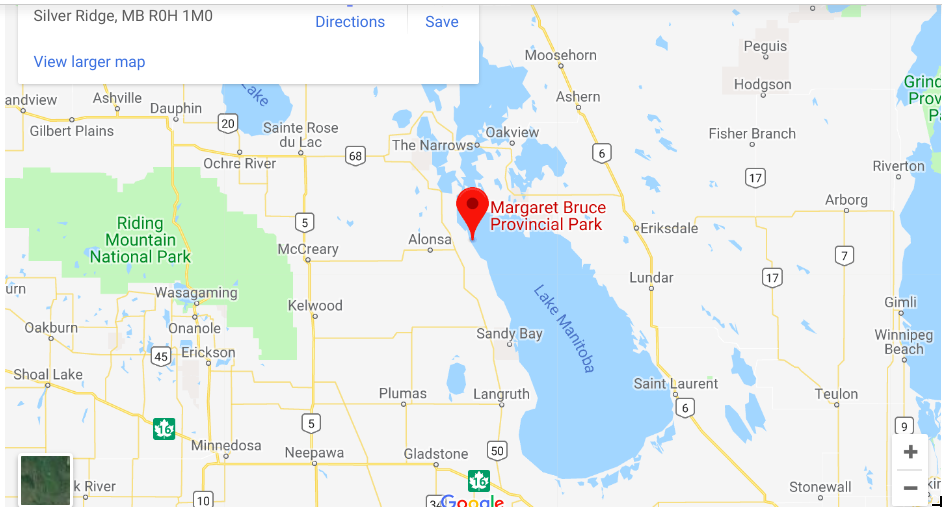

Today on our trip we'll end up in McCreary landfill site which is

a stone throw from Alonsa where a tornado destroyed homes and cabins yesterday.

The only landfill site we're not allowed to pick from on this map are Neepawa and Minnidosa, all the other small towns are fair game. Those small towns on the shores of lake Winnipeg are not worth bothering with.

Pat has packed a huge lunch box with a few coolers, we'll leave home around 9:00 am and be back around 6:00 pm.

Last edited by Proton; 08-04-2018 at 06:49 AM.

|

|

wish u all the best but PLS post pics.

Three sites visited and we missed Erickson by 10 minutes gates closed, two elctric motors one is a half horse and the larger one if one horse these will be saved for personal projects and not opened up for the copper.

The motors both came off of some sort of refrigeration system, both are 220 volts single phase.

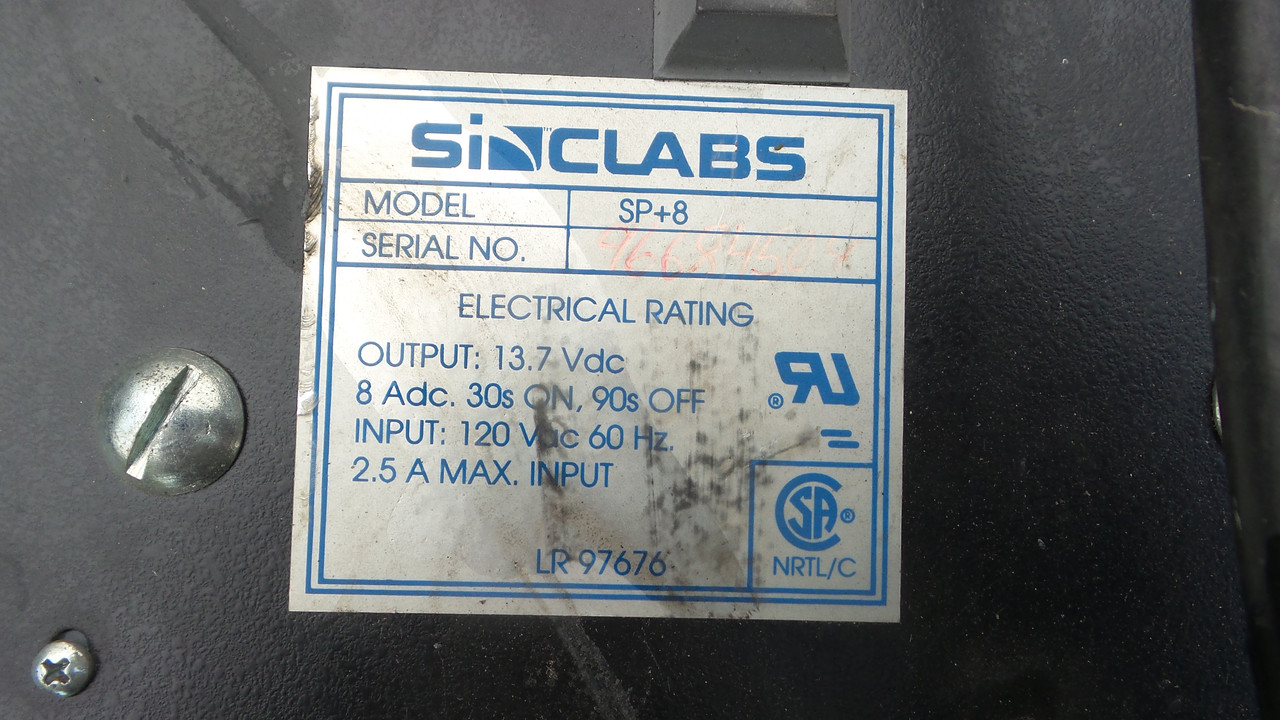

Heathkit capacitor tester, Heathkit signal generator and a tube tester, the black box is a 12 volt power supply for a radio base station and the box of circuit boards to do some testing with the solder looking for traces of gold. The trying to recover the tin electrically via electrolysis

.

Not a very productive day as fa as prizes went but good to get out for the day, we enjoyed ourselves and will probably make this run one more time before the snow arrives.

Last edited by Proton; 08-04-2018 at 04:05 PM.

Some fun facts, recovered from one small mother board 7.9 grams of solder and there's probably enough left of the board to make up a full 10 grams. One metric ton has 1,000,000,000 grams so it would take one hundred thousand boards to get a ton of solder.

If there is 250K worth of gold in that solder each board in solder alone is worth $2.50 just from the solder. I think that I need to find another hobby.

From the crust that formed on the tin solder button you can tell it's not pure tin.

That nice base station power supply went up in smoke.

I'm going to gather up a few more pounds of this stuff then fire up the induction furnace to see if it melts. Until then I'm not going to speculate what it might be.

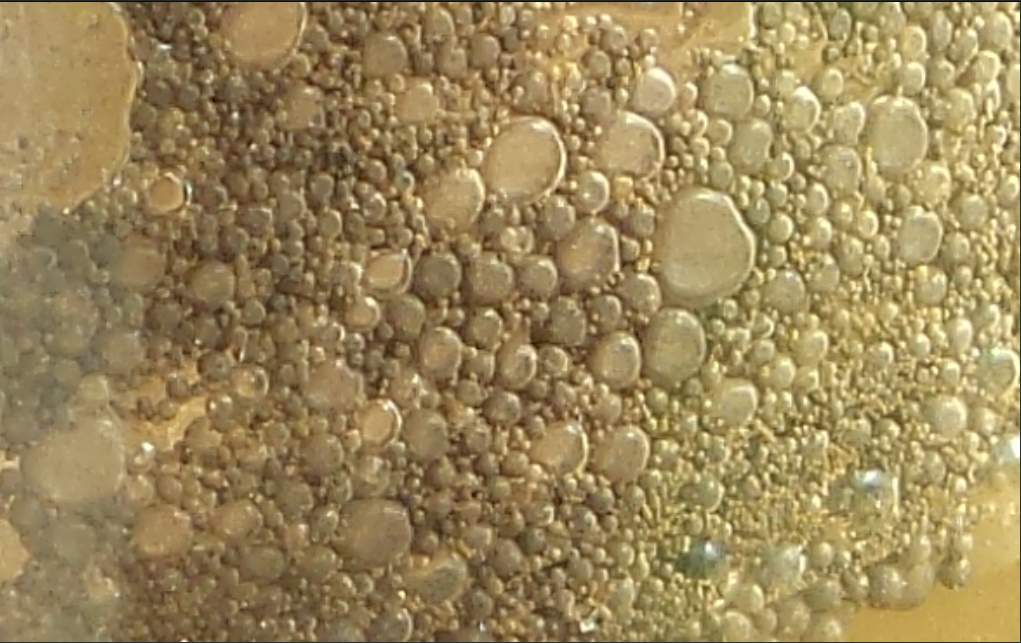

Another puzzle these globules formed after skimming the float from some crushed black sand I received from a friends placer claim in northern BC. try as I might I can not get the little globs to rejoin or sink to the bottom.

Its just water with a bit of soap added to break surface tension. The globs are stuck to the side of the jar in this picture.

|

|

Rinse and strain, once your back to product in clean water add a few drops of jet dry, which is a surfacant and will break the tension without having to deal with emulsification.

After than you should be able to pan off the super fines and suck them up manually along the line you create while panning.

Next time, when dealing with black sand, try screening it dry first. Run each mesh minus on it's own starting with the coarse and working down, when they are uniform you can get the gold off WAAAAAAY easier. Hope that helps.

WI ITAD LLC, IT Liquidation Services, we remarket, buy and sell scrap electronics No customer too large or small!

This came from a 10 lb sample that I first crushed in a pipe with a base welded onto it then using a heavy steel shaft, did not crush as fine as I had wanted but this was the first float to come off. I'm going to ball mill the sample again, I want a very fine powder.

I do not want to pan, this is leading to a flotation cell to recover values.

With a bit of vigorous shaking the globules did break up, just thought it was an interesting photo and had to share.

Will not get into details on the process's used but will post any images of interest.

The heavies in the first image were hand panned from same material shown in the second image shown bone dry, third image same chunk of compacted clay only this time its wet with water and the last image has dead centre what looks to be a small metal flake,

The ball mill is currently loaded with about 100 pounds of this material, the heavy material is what I'm after for my induction melt. I'm curious if I can produce a metal button.

Time to stop fooling around and send a small sample out for a legitimate assay.

Last edited by Proton; 08-06-2018 at 12:26 PM.

Now wouldn't that be a hoot I'm out looking for gold and find a lithium deposit.

Lithium recovery from hard rock and clay deposits normally involve a series of physical processing steps (e.g., milling and flotation) combined with other hydrometallurgical steps (e.g., such as leaching from where solution is also subjected to impurity removal stages) to remove unwanted elements before being precipitated as lithium carbonate. SRC has worked with companies in Canada, Australia and USA to recover lithium from spodumene, lepidolite, petalite, smectite, illite, pegmatite and other lithium bearing hard rock ores and clay deposits.

It's definitely sedimentary clay.

|

|

lithium salts are not particularly value on a less than industrial mining scale.

Just trying to give you some advise, it has less to do with your process and more to do with the screening size of the material you run. When it comes to really recovering as much as you can, uniform particle size is more important than the particle size itself. If you screen out say 80 mesh minus you should get a much better result than trying to mill it down to a flour like base on its own. Densimetric separation works really well when particle size is as uniform as possible. Don't take that as me telling you what to do, that's me giving you some insight on what I do and we are recovering 99.97% the product we want.

I wanted to add this, if your looking to do this mechanically and not by hand, get a small spiral classifier if you dont have one, they are good at doing product with very close densities.

Last edited by armygreywolf; 08-07-2018 at 08:25 AM.

Sent a sample out for an ICP assay and should know within a week or so what is in that clay.

As for investing in mining equipment not going to happen, if the assay should come back with positive results then I will stake the ground then sell the claim to someone or a company with more resources than I have.

When I have received the assay report will post the results wither they're good or bad.

My ball mill hard at work liberating the embedded heavies, once the clay has been cleaned I'm going to check with one of the local potters to see if its suitable for their needs.

Found another free RV trailer at one of my favourite landfill sites, I'll be picking it up this upcoming weekend.

The guy that installed the new glass in my Dakota project gave me an older Sea Horse 7.5 hp outboard, this will fit nicely on the free aluminium boat a neighbour gave me a few months back.

I hope that I can get the old Sea Horse to run half as good as this one in the tube vid.

My assay report came in this morning, best money I ever spent. There's enough rare earth elements to economically mine.

The rust stain is not iron.

I've calculated the most valuable elements from the assay from their parts per million that sample below has a value or approximately $4,000.00 USD per metric ton.

And yes it has been confirmed that lithium is one of the elements but in itself does not make up for the total value there are minerals in the sample with more value than Li.

Last edited by Proton; 08-21-2018 at 10:09 AM.

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks