I have a deep seated hate of fitting universal joints.

It never goes to plan, I'd guess even after making real real sure all of the roller bearings are in place...

10%+ of the time a single roller falls over & gets stuck in the bottom of the end cap...

Meaning the things gunna start wearing out from the first second its used.

The story with fitting a universal in a drive shaft, more often than not, in the factory, they actually just fit the uni & weld a steel washer in over it to hold it in place.

Or pein the edges over, like this >

Then they balance the shaft.

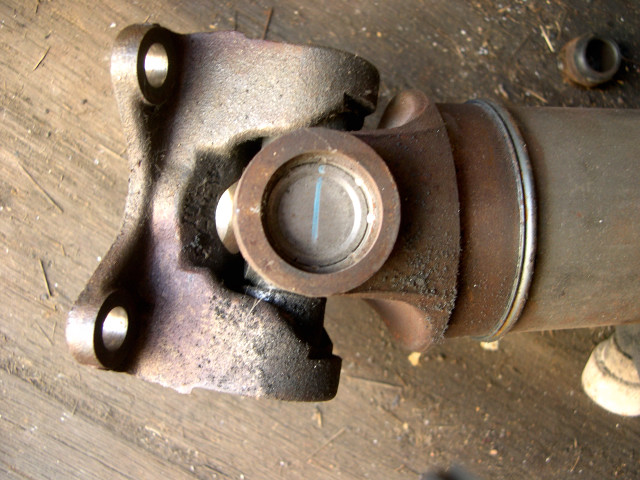

4WD's & such can have a circlip in place, like this >

Or they use a clamp thing with bolts to hold it in place.

Like this >

With the welded washer or the peined over edges ...

When one wears out, the driveshaft place has to remove the shaft while the cars on a hoist.

Grind off the tack welds, punch the universal out a bit & remove the washer, times that by 4 for each universal...

Then remove the actual universal, ream out the holes so they are smooth & round, often they have to bore it out a bit (and inline with the centrelines...) so then they now have to source the correct size universal.... After starting the job...

Then they have to set the yoke ends up in a milling machine & cut the circlip grooves in the correct place, thats a pain in the rs..

Then they get the correct size universal & fit it ('bags NOT ME!') get it close to centre.

Real real close, they use a dial test indicator....

Fit the spacing washers over the universal ends, & then the circlips...

Make sure they won't fall out... A tiny bit of swarf or grit will not let them seat properly & then they fall out, under the vehicle... while its at speed...

Ever seen a car jump 6 feet in the air while also jumping sideways by 6 feet? Thats what a loose driveshaft does...

Then they put the driveshaft in a multi thousand $$ machine & balance it....

Then they refit it & prime it with grease.

And... Oh yeah... universals all seem to wear out at about the same time... so you do all of the universals on the shaft at the same time.

Or you have a vehicle thats in for repairs every 6 months for the same job......

------------------

Oh, to test a universal, get under there & grip the shafts on each side of the universal with each hand.

Now give it a twist in different directions (left hand clockwise, right hand anticlockwise).

Now give it a twist in the other directions.

If theres a 'lag' or 'slop' or a 'clunk' when you reverse directions, the universals worn.

They can still work for a long time after wearing out a bit, you end up with the effect of a time lag when you take off from a standstill, when its worse you can hear the 'clunk' as well.

Check that & also to see if the end caps are welded in place, if they have circlips the jobs a LOT easyer.

I got quoted NZ$400 + to do the driveshaft on my car in 2000, so US$400's probably cheap if they are doing them all.

Bookmarks