Please add thanks to first post

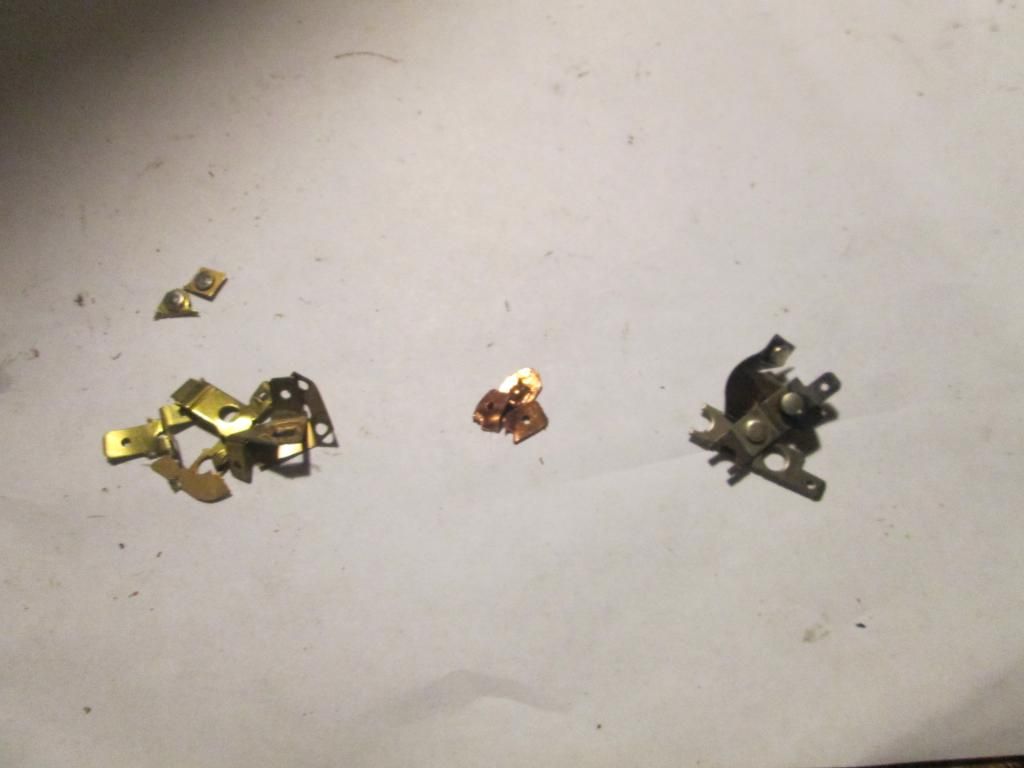

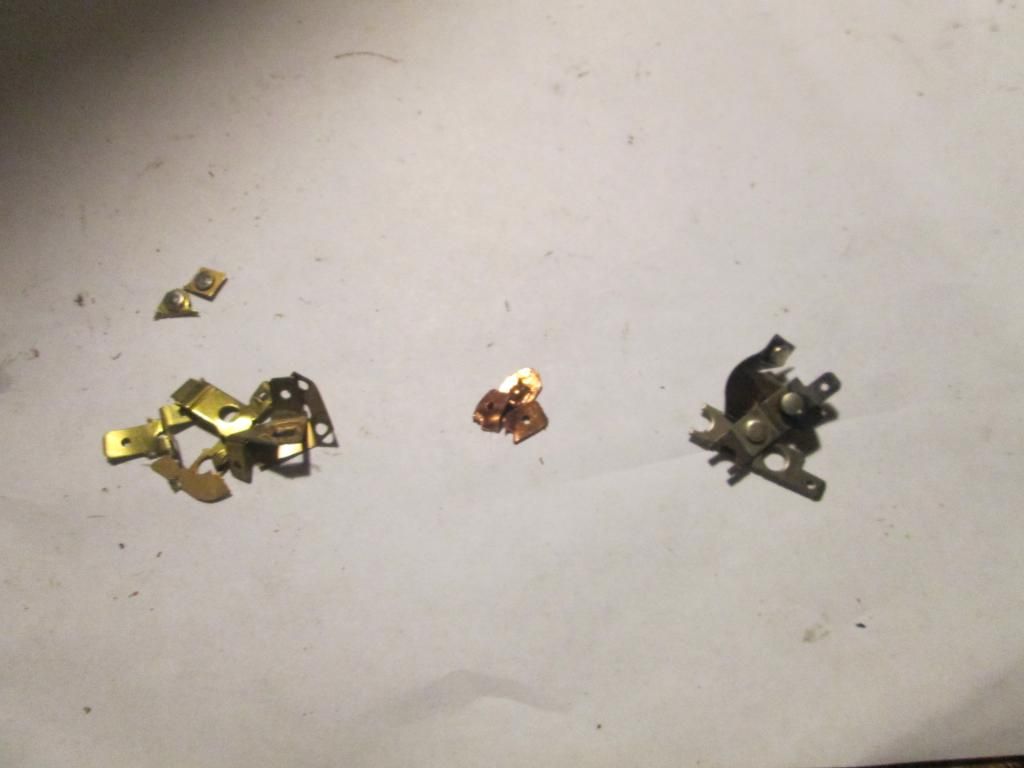

The bits of copper and brass from the switches and a couple of contacts.

[IMG]

[/IMG]

Now pull the rotor out, some tapping with a hammer to get it started. Clean the stator however you do it

[IMG]

[/IMG]

to separate the rotor from the Al Remove the C clip

[IMG]

[/IMG]

Pry off the bearing and the spring assembly will fall out. There will be a bearing in the cast a few hits of a hammer takes it right out. The last piece on the cast Al was a GPM control which had a hex screw holding on the knob and then simply unscrew the brass adjuster the smaller brass pin is underneath.

cut or unhook the springs on the rotor to get the two last pieces of cast AL. A hammer works well if they resist.

leaving you with

[IMG]

[/IMG]

Edit: Not in pic Power cord, brass prongs pulled weights the same

Totals were

1/4 lb AL winding

5 oz copper

9.1 oz of yellow brass (with wire ends)

2 lbs light steel

11 lbs prepared

2.4 oz insulated wire

4.5 lbs cast Al

Selling as a motor I would have made $2.15 in a couple minutes of work current prices

It took 30 min to tear down the motor and another 10 to get the windings out (which were half Al). After breakdown I would make $5.55 current prices.

The gun hoses and fittings are all in good shape and will be resold.

Tools

Drill, (standard, phillips, 3/8 bit )Pliers, hex wrench, prybar, cutters, oil bucket, hammer, chisel.

Any questions feel free to ask.

[/URL][/IMG]

[/IMG]

Register To Reply

Register To Reply

-

-

Bookmarks