Thanks to all that responded. I was working all day and just got a chance to view the thread. No I was not working on the water tanks, still on a farm I have been on all winter.

First, thank you to oldtoothlessbassmaster for rescuing my picture. I tried to post it and was unsuccessful. I immediately deleted the post and he saved it for me.

I plan to cut it with propane. My son will be joining me for this project. I was a millwright when going to school and made the transition to propane this winter. I am not the best, but this project will make me better. I plan to use liquid oxygen on the water tanks because I plan to cut non stop.

I have a scraping trailer complete with Miller generator/welder, air compressor, three K oxygen bottles, 100lb. propane bottle, and tool boxes. There is also two Smith torch sets with scraper heads. This was made out of a two horse trailer that was scrap on my first job. I have thought about purchasing metal shears for my skid steer and might with this project. I borrowed a

plasma cutter this winter but my generator could not handle the load. Since all of my work is rural, it would not be a good investment until I get a bigger generator.

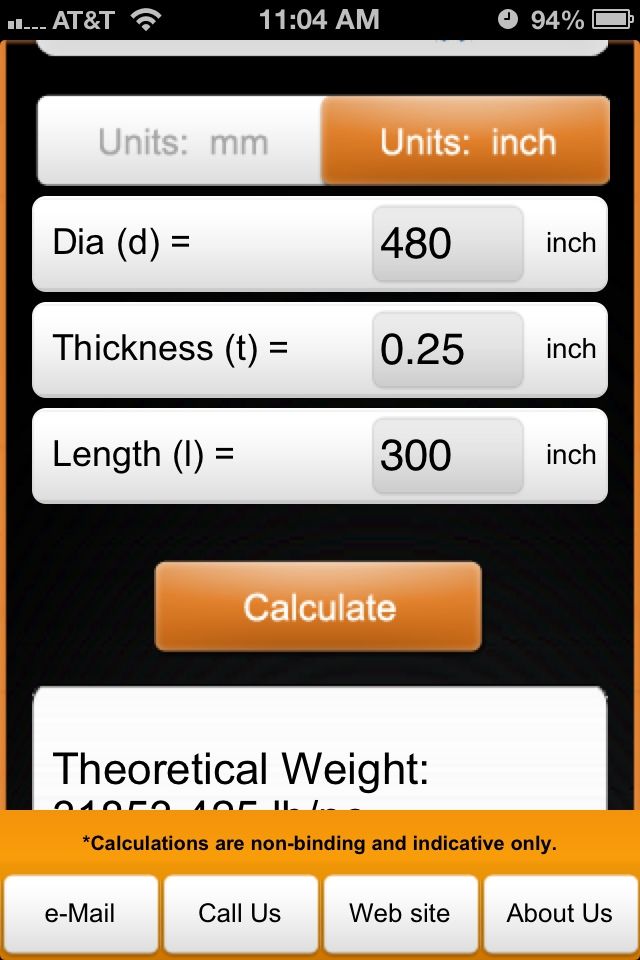

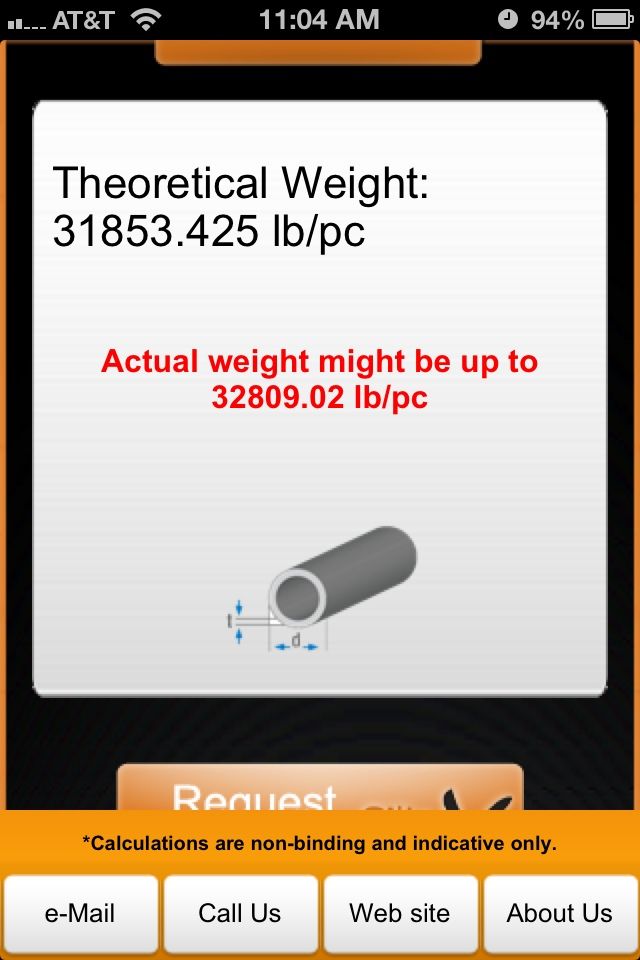

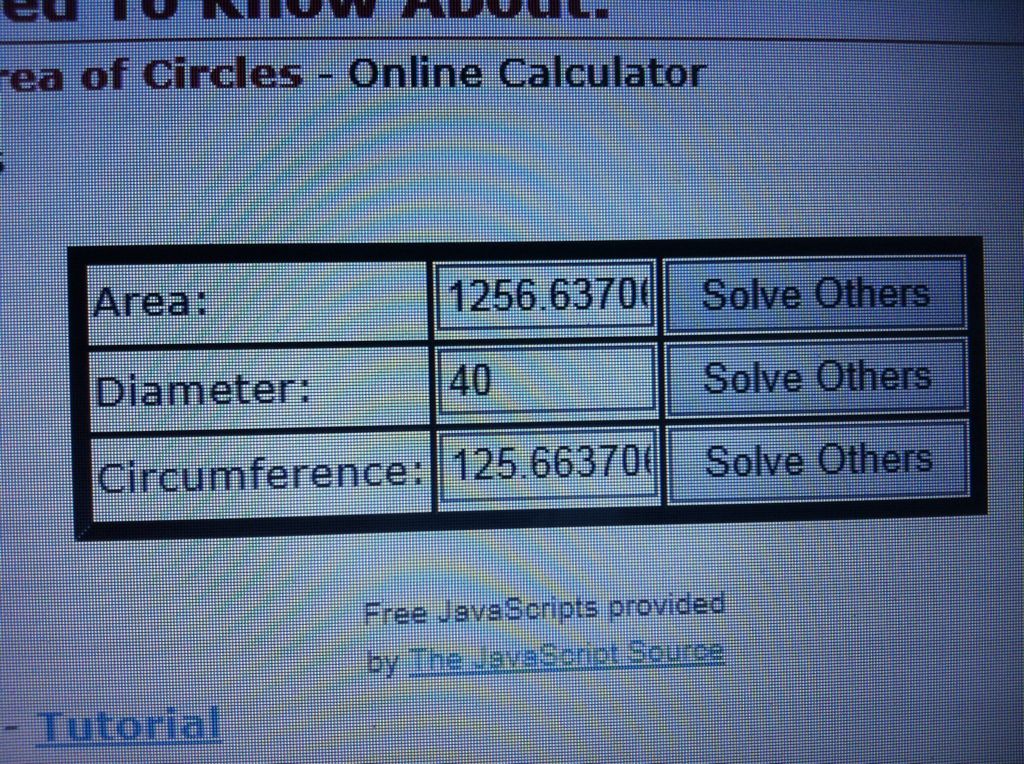

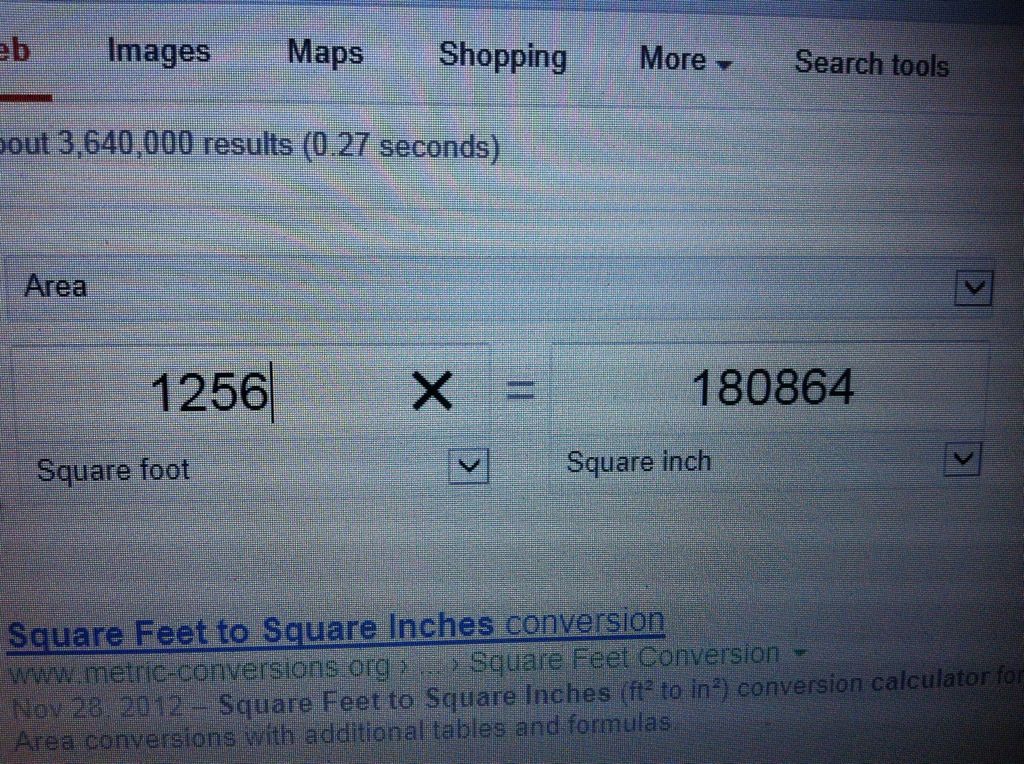

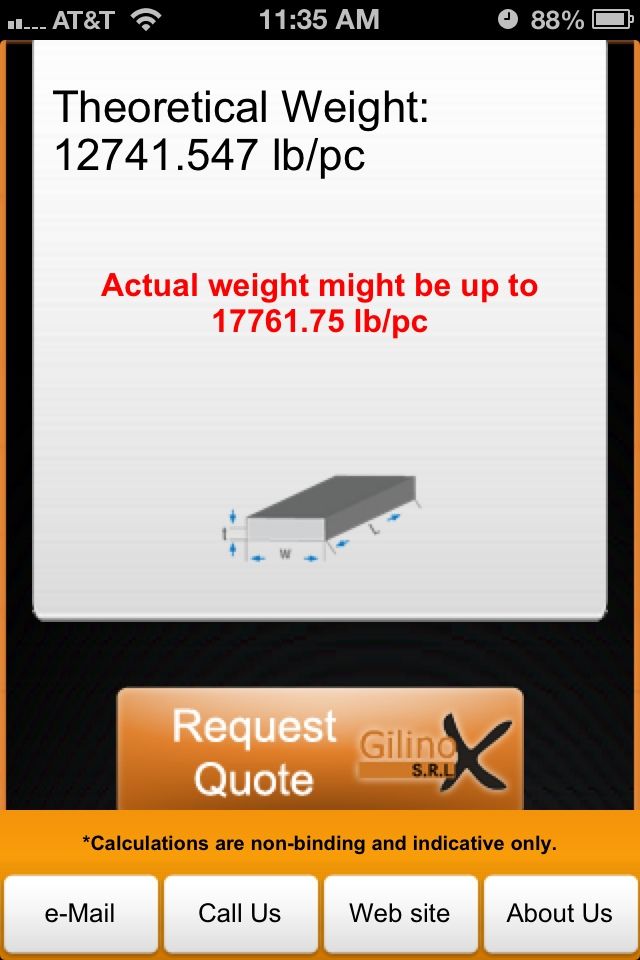

I appreciate Cory's ideas and calculations. The concern about the structure springing is a real concern of mine. I like Auminer's idea, but I was told that dome roof tanks do not need an internal structure. I will not know until I cut Cory's door. Combining Cory's and Auminer's ideas might be the best strategy. Based on what I have heard I think cutting slices like you mount a tire on a truck would be worth researching. If it does not have an internal frame, the roof will be the first to go. I have an agreement with two scrap yards to cut the pieces into 5ft. X 18in. slices.

Old Dude reinforced the reason I posted this thread. It is all new to me and I would like to haul the last load into the scrap yard instead of being buried under it.

This is a once in a life time opportunity, so I would appreciate any additional insight.

Register To Reply

Register To Reply

Bookmarks