Originally Posted by

src3collector

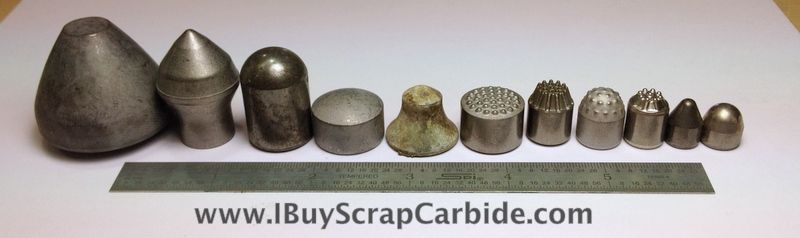

those are known as rotary drill bits they operate on electric rock drills and cut in to rock by turning at a very high velocity, typically 15" wide and entirely disposable...once the carbide buttons are flat they are thrown out (and i can get my hands on them as well, for free)

also although only a tiny bit of the carbide protrudes through the face they are buried in pretty deep, if they werent they would break out of the steel too easily while drilling (bits get scrapped according to how many buttons have broken off, and typically once one button breaks in the hole while drilling the shard of carbide will knock out several other buttons before getting blown out of the hole, a lot of the times causing nearly brand new drill bits to be scrapped)

however the bits i deal with directly at work are on diesel powered rock drills and use a pneumatic cylinder with a piston that pounds up and down while only spinning at a very slow speed, the pounding from the hammer is what breaks the rock apart in these, not the speed at which it is turning

i had some spare time at work today so decided to see what it would take to simply use a hand grinder with a 5"x5/16" disk, took me roughly 45 minutes and 1 grinding disk, im holding on to 3lbs of carbide (with no brass braze still attached)

those 3 crates are the amount of scrap we go through in 1-2 weeks

Register To Reply

Register To Reply

-

-

Bookmarks