Hi, I'm from Argentina and I'm going to build a Copper wire stripper

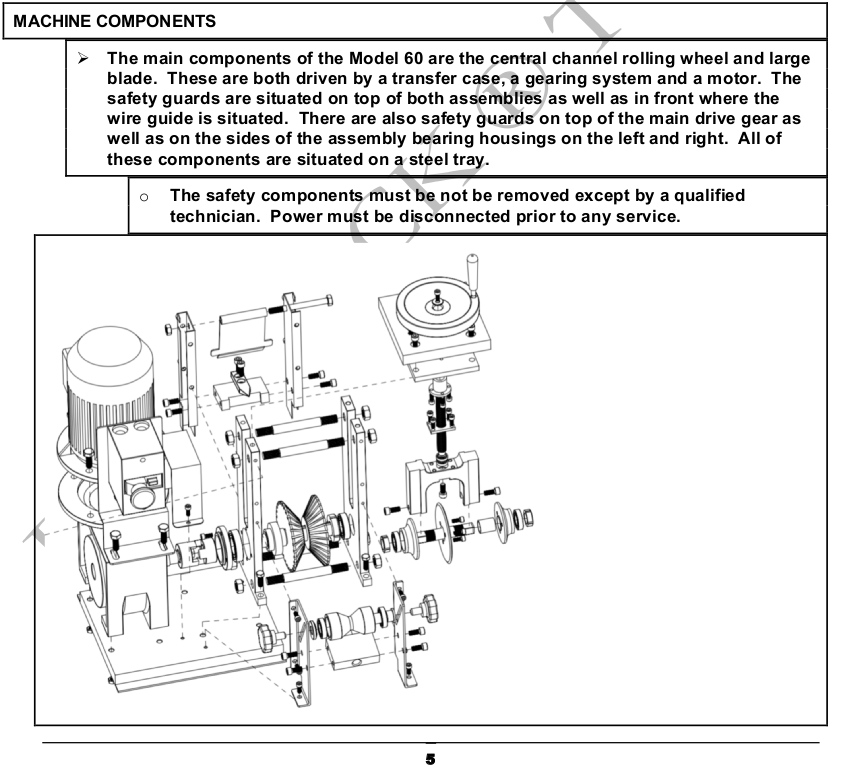

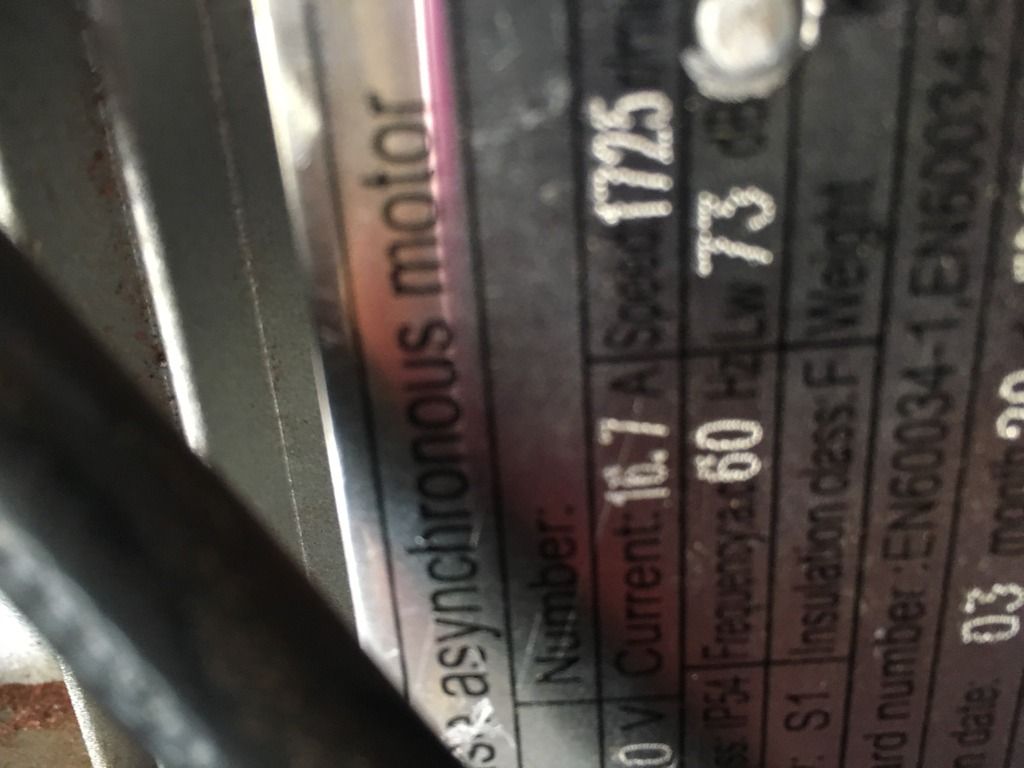

My idea was to build a similar one to the GENSCO CSX-001. I'm going to use a 2HP engine (1450 rpm).

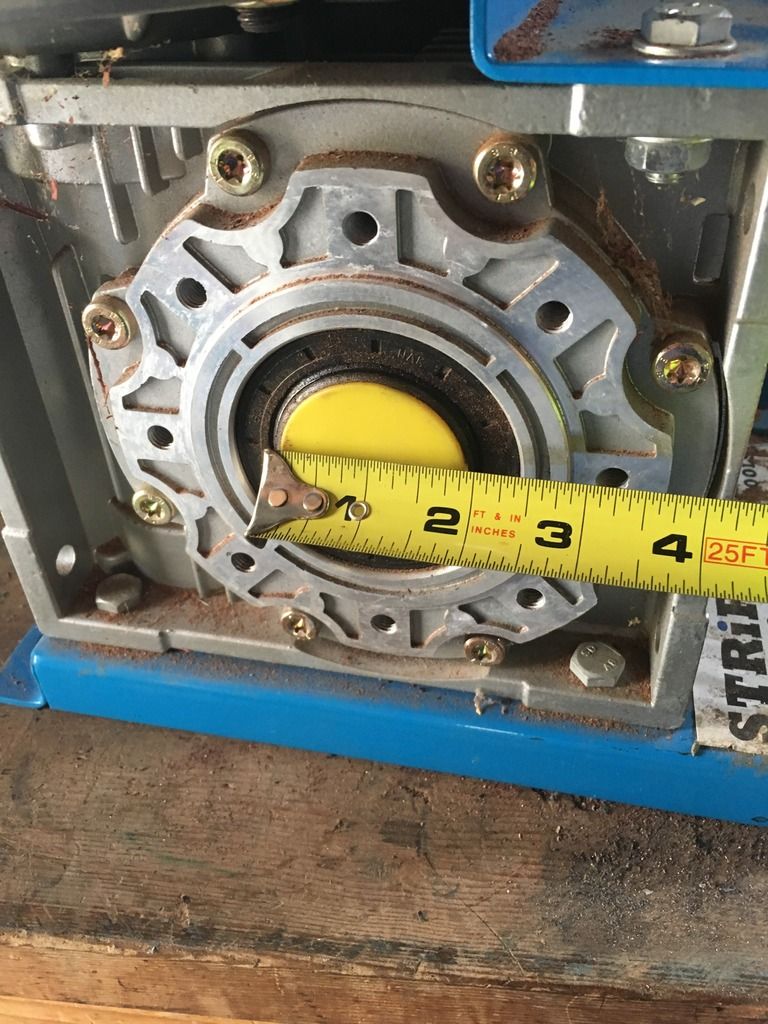

I have 2 doubts: What reduction does it take? 20/1? What size is the "V" traction roller?

I hope someone knows how to solve these doubts. I promise to put photos of the entire construction process and videos of the machine working. Thank you very much.

Sorry for my English...

- Homemade Copper stripper. DOUBTS

- Homemade Copper stripper. DOUBTS

Register To Reply

Register To Reply

Bookmarks